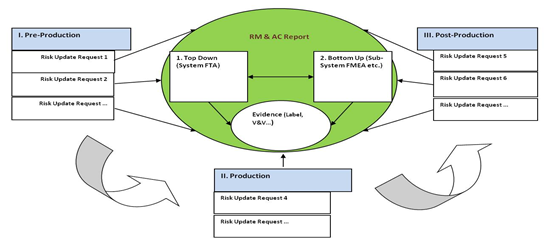

Risk Management Life Cycle

The industry best practices of risk management typically start from the top down system analysis (e.g. preliminary hazard analysis and fault tree analysis), followed by bottom up analysis (e.g. FMEA) as more design or process information becomes available, as illustrated in the following table.

Life Cycle Process |

Input |

Output |

||||

Hazards |

Hazardous Situations |

Failure Modes |

Causes |

Risk Controls |

||

System Hazard Analysis |

Intended use, use conditions, historical data, guidance, standards |

<=======Focus=========> |

Safety Feature Identification |

|||

System Fault Tree Analysis |

Safety Features, System Requirements and Design, Safety Features |

<============Focus===========> |

System Safety Requirements |

|||

Sub-Hazards and Sub-System FMEAs |

Sub-system Requirements & Design |

<=======Focus==========> |

Sub-system safety requirements |

|||

Component/Unit/Process FMEA |

Component/Unit/Process Information |

<=======Focus==========> |

Component/Unit/Process safety requirements |

|||

Production |

Production information, design/process change |

<=======Focus==========> |

Production safety requirements |

|||

Post Production |

Field Performance/Industry Information |

<=====================Focus======================> |

New/additional safety requirements |

|||

TurboAC™ provides the capability for its user to perform risk management activities following the best practices. With TurboAC™, the user is able to perform both top down and bottom up analysis in parallel with the product development and post market maintenance. The user can define and configure the product life cycle risk management process, initiate change requests, assign owners, track status, capture results and manage reviews and approvals for each file updates. These change requests can be triggered by a design change, a CAPA, a complaint etc.