Risk Analysis ( Hazard Analysis, FTA and FMEAs )

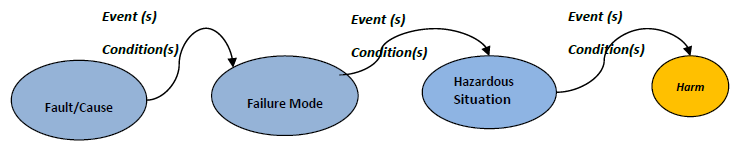

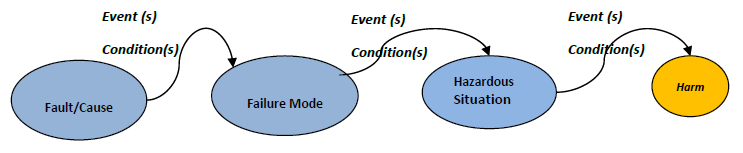

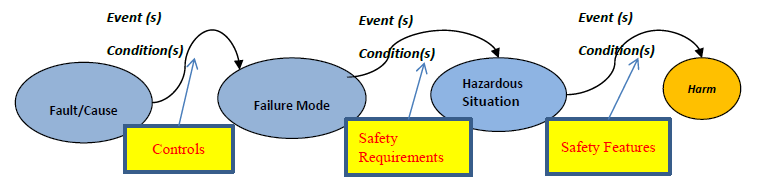

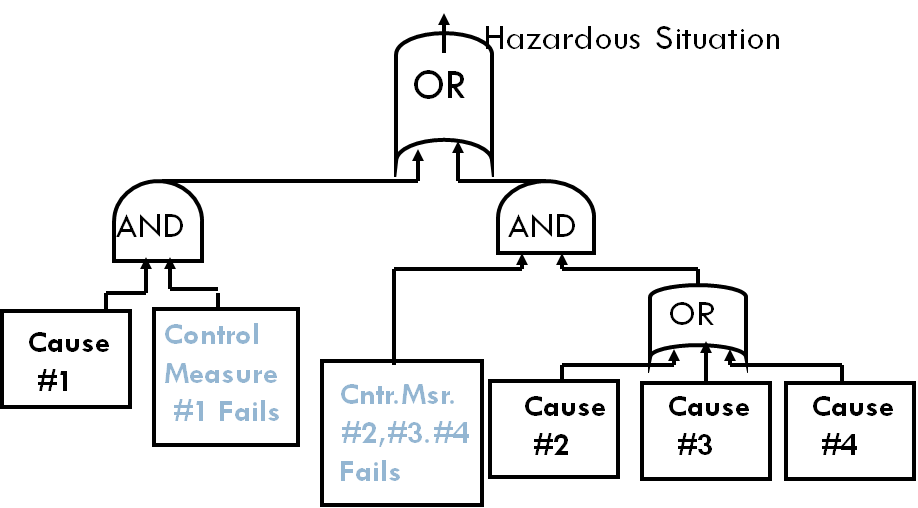

A key part of risk analysis is to identify applicable hazards and harms, hazardous situations, failure modes, causes and contributing factors (e.g. events and conditions) including their cause-effect relationships (thereafter referred to as causal chain as illustrated in the diagram below) for a product or system. A comprehensive understanding of these causal chains can help to assess the likelihood of harm occurrence, identify and optimize risk controls, and enable proactive design for safety.

There are multiple techniques that can be used to identify the casual chains. In general, these techniques can be grouped into two categories: Top Down Analysis (e.g. System Fault Tree Analysis) or Bottom Up Analysis (e.g. Sub-System FMEA).

TurboAC™ provides the capability for user to perform both Top Down Analysis (e.g. Fault Tree Analysis) and Bottom Up Analysis (e.g. FMEA) within itself.

Top Down Analysis

A Top Down Analysis begins with identifying top system hazards, hazardous situations, sequence of events, and potential harms for a product i.e. Preliminary System Hazard Analysis as illustrated below. This can be started at early stage of a product development cycle.

For an identified hazardous situation, further top down analysis is to deductively identify potential specific causes and events including any contributing factors that can lead into the hazardous situation, i.e. a fault tree analysis for the hazardous situation.

With TurboAC™ software, users can facilitate the group brainstorming, document, edit and present the results in either graphic format or tabular format. This will include:

- Define and identify potential harms.

- Define and identify applicable top hazards.

- Define and identify applicable hazardous situations.

- Identify sequence of events (failure modes, causes, conditions etc.) that can lead into the hazardous situations.

- Identify system level risk controls strategy

- Perform a fault tree analysis

Hazard Category |

System Hazard |

Hazardous Situation |

Harm |

Sequence of Events |

Risk Control Strategy |

Bottom Up Analysis (e.g. Sub-System/Design/Process FMEA)

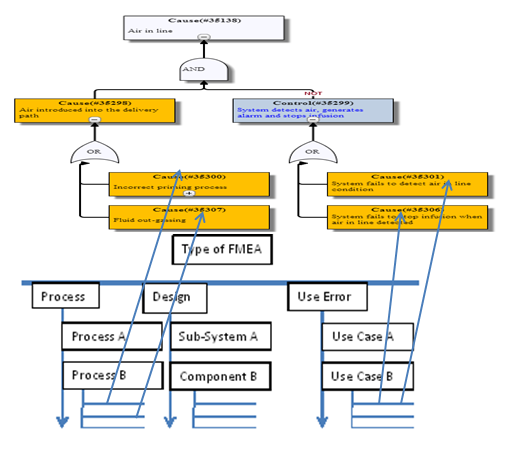

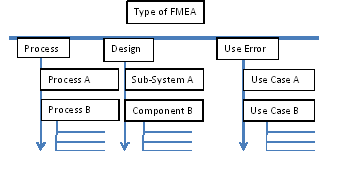

A Bottom Up Analysis (Design FMEAs, Process FMEAs, Use FMEAs, or Common Sources of Hazardous Situations) is to identify low level causes that can potentially contribute to hazardous situation occurrences. This is to analyze common sources of hazardous situations (common failure modes, defects etc.) and/or individual sub-systems/components, to identify failures, causes, effects and risk controls as needed. With TurboAC™, users can perform any types of bottom up analysis and as many as needed.

Connect Results of Top Down Analysis and Bottom Up Analysis

Being able to connect and consolidate the results of Top Down and Bottom Up analysis can help to:

- know the exact effects of a FMEA failure mode in relation to hazards and harms,

- understand the end to end causal chains for risk assessment and control identification,

- provide multiple views to assure completeness in identification of hazardous situations, failure modes, and causes.

With TurboAC™, the connectivity between the Top Down Analysis and Bottom Up analysis is one click away. TurboAC™ software provides the capability to automatically passing down/up the severity and probability effect between Top Down and Bottom Up analysis results, and automatically identify the worst scenario (the most critical causal chain) for a system or sub-system.